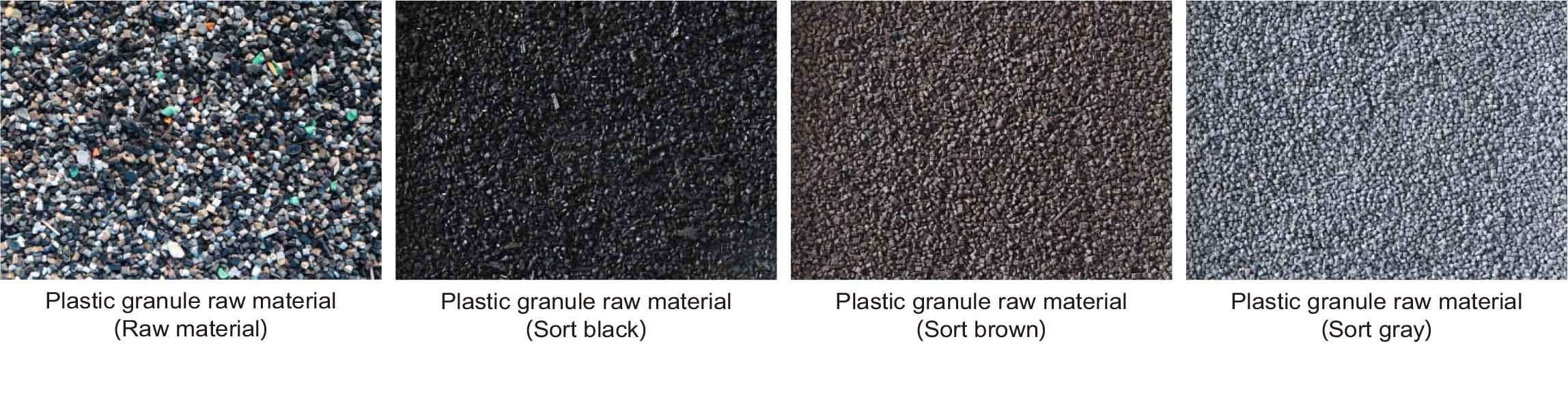

The Mihoshi Plastic Selection Intelligent Sorting Machine can sort different types of Plastic

Product Introduction

Mihoshi Intelligent Color Sorter has an excellent sorting system, suitable for various plastic sorting and grading, ensuring sorting quality, and helping to create standardized and diversified plastic products. Efficient sorting of difficult defects, with stable high-precision sorting system, high yield, energy saving, simple operation, convenient use, and long service life. Use the Mihoshi plastic color sorter to sort plastics.

Application Field

Suitable for sorting multiple categories of plastics such as PET plastic, PVC plastic, PE plastic, PS plastic, PP plastic, etc.

Product Specificities

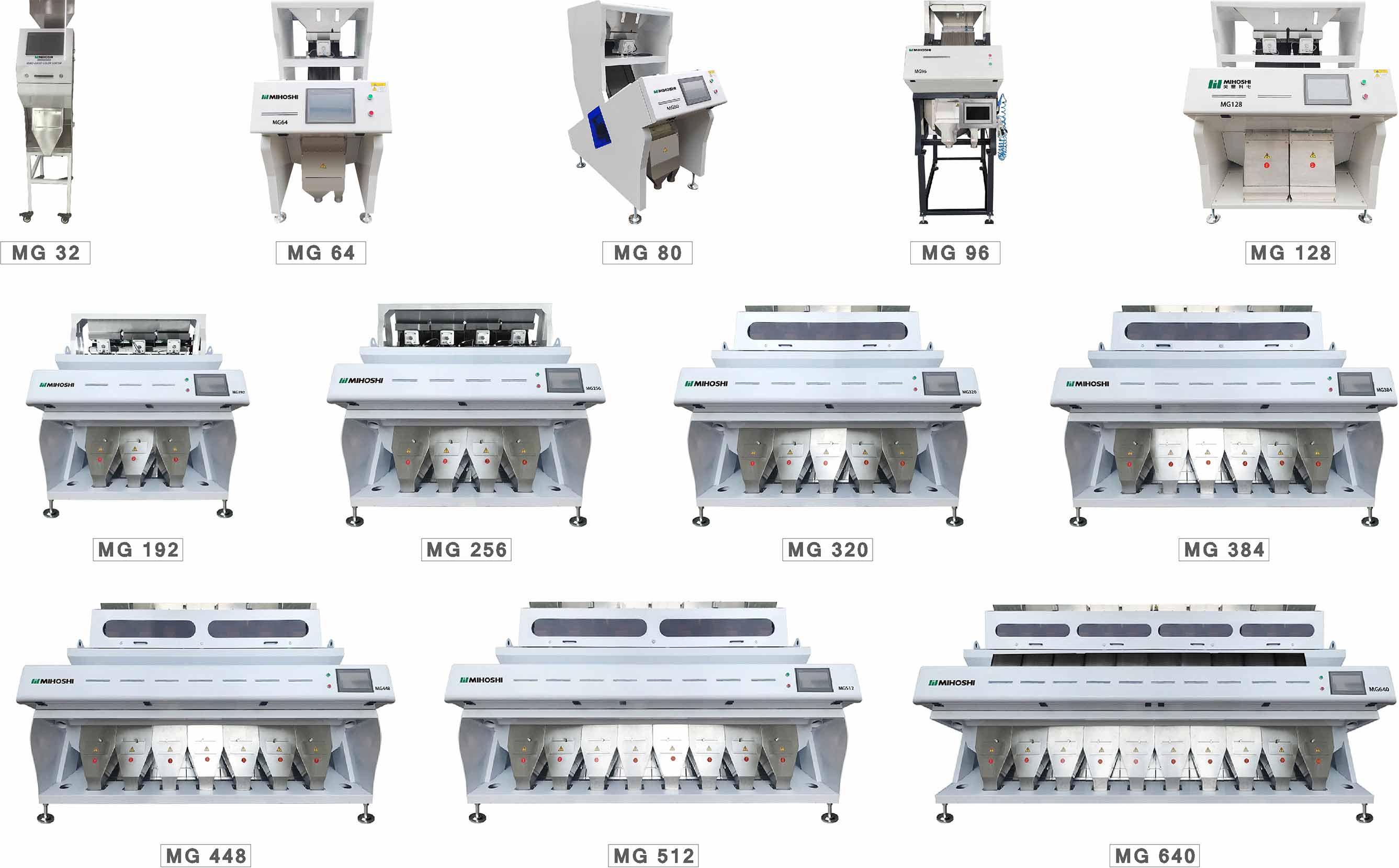

Product models of Chutes color sorter (part)

Technicial Specifications

| Product model |

Capacity (T/h) |

Accuracy (%) |

Voltage (V/Hz) |

Power (kW) |

Air pressure (Map) |

Air consumption (L/min) |

Weigh t(Kg) |

Dimension (mm) |

| MG32 | 0.2-0.5 | >99.99% | 220/50 | 0.5-0.8 | 0.6-0.8 | 0.1-0.3 | 120/180 | 590X1504X1760 |

| MG64 | 0.8-1.6 | >99.99% | 220/50 | 0.8-1.5 | 0.6-0.8 | 0.3-0.8 | 300/350 | 880X1504X1760 |

| MG80 | 1-2 | >99.99% | 220/50 | 1-1.8 | 0.6-0.8 | 0.3-0.8 | 350/400 | 900X1504X1760 |

| MG96 | 1-3.5 | >99.99% | 220/50 | 1.2-1.8 | 0.6-0.8 | 0.4-0.9 | 300/400 | 1550X940X1750 |

| MG128 | 2-6 | >99.99% | 220/50 | 1.3-2.2 | 0.6-0.8 | 0.5-1.0 | 700/860 | 1314X1504X1760 |

| MG192 | 3-9 | >99.99% | 220/50 | 1.5-2.5 | 0.6-0.8 | 0.8-1.5 | 950/1000 | 1650x1504X1760 |

| MG256 | 4-12 | >99.99% | 220/50 | 1.8-3 | 0.6-0.8 | 1.0-2.0 | 1100/1200 | 1986X1504X1760 |

| MG320 | 5-15 | >99.99% | 220/50 | 2.2-3.7 | 0.6-0.8 | 1.3-2.1 | 1280/1350 | 2322x1504X1760 |

| MG384 | 6-18 | >99.99% | 220/50 | 3.6-4.5 | 0.6-0.8 | 2.0-3.5 | 1400/1500 | 2658X1504X1760 |

| MG448 | 7-21 | >99.99% | 220/50 | 4.1-5.5 | 0.6-0.8 | 2.5-4.3 | 1500/1600 | 2994x1504X1760 |

| MG512 | 8-24 | >99.99% | 220/50 | 4.7-6 | 0.6-0.8 | 3.0-4.5 | 1700/1800 | 3330X1504X1760 |

| MG640 | 10-30 | >99.99% | 220/50 | 4.5-7.5 | 0.6-0.8 | 5.0-6.5 | 2000/2250 | 3666X1504X1760 |

| MG768 | 12-38 | >99.99% | 220/50 | 5.2-8.8 | 0.6-0.8 | 7.0-8.5 | 2500/2600 | 4200x1504X1760 |

Product Specificities

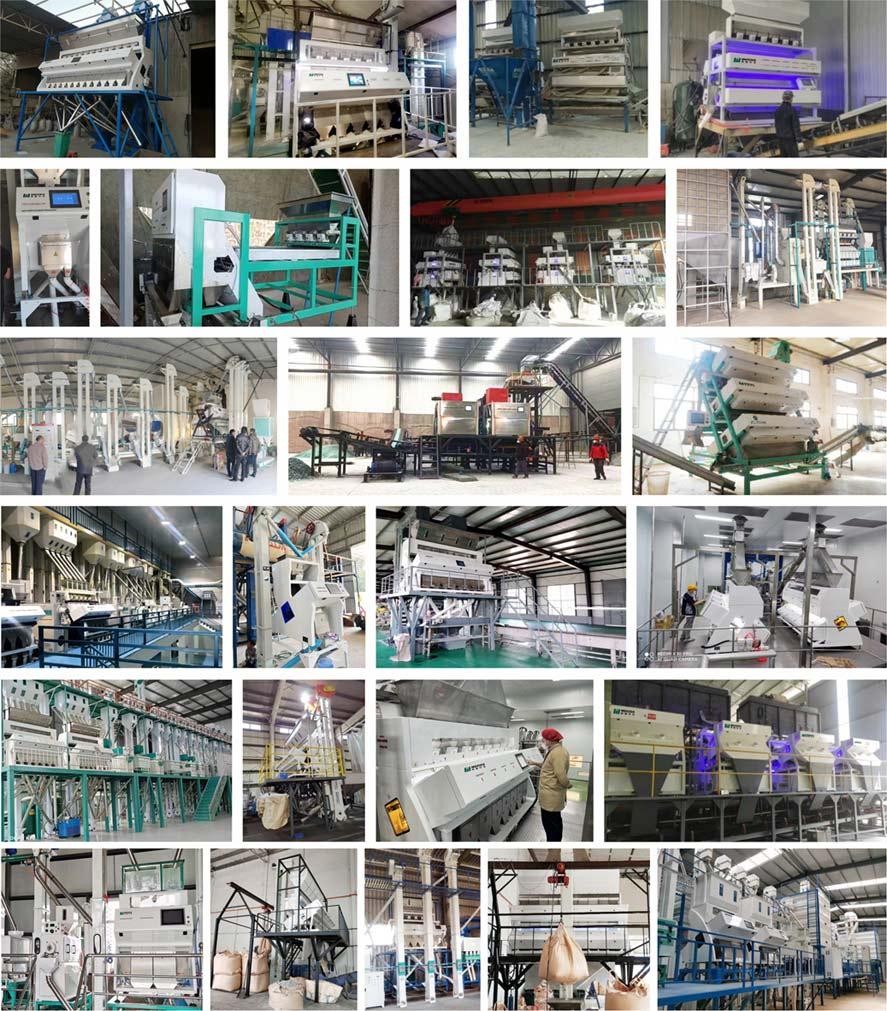

Installations

Our Strengths