SERVICES

Operation instructions

Startup steps

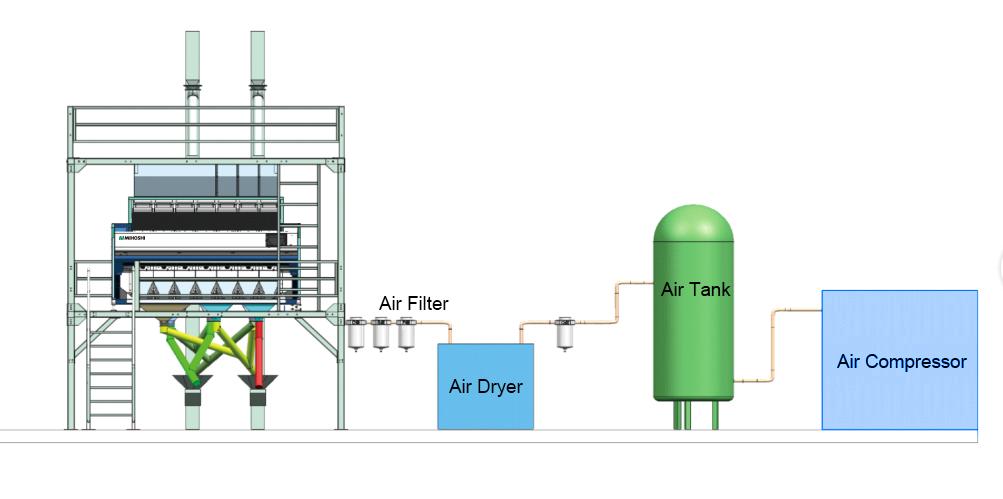

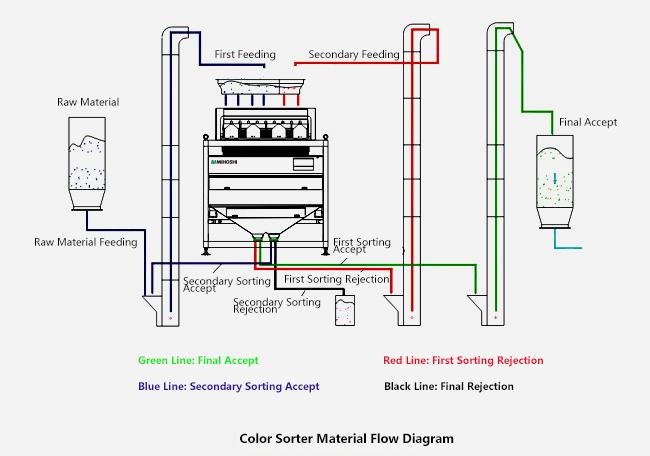

Before running the machine, it is necessary to ensure that the power supply of the color sorter is normal. The air pressure in the storage tank is sufficient. The operation steps include startup steps, normal color selection steps, and shutdown steps.

Press the green power button on the machine panel to enter the boot system while ensuring that the circuit and air circuit are connected and everything is normal. Wait for the interface to load and enter the main interface.

Air pressure setting

The required air pressure range for the color sorter to operate normally is approximately 0.2-0.4 MPa. The setting of air pressure is determined based on the size of the color selection material, and the position of the air pressure gauge is adjusted as shown in Figure 5. The place marked by the red circle is the pressure regulating valve. The air pressure adjustment method is to pull down the rotary button of the pressure regulating valve in the figure to unlock it, and then rotate it. Turning to the right increases the air pressure; Turn left and the air pressure decreases. When adjusted to the appropriate value, push the rotation button upwards to lock it.

Circuit installation instructions

The power supply of the manufacturer's color sorter mainframe in China is single-phase 220V ± 5%, 50Hz AC power supply. The total power of each series of color sorter mainframe is different, and the connection to the mainframe harness is selected according to the actual model power.

To avoid interference, a separate grounding wire (2m or more) must be connected to the color sorter host, and good grounding must be ensured.

Air compressor: The various parameters of the air compressor provided by the manufacturer are determined based on the models of different color selection machines. Specific parameters can be found in the air compressor manual, but their working power supply is three-phase 380V ± 5%, 50Hz. Please use different electrical switches and power cables according to the power of the motor.

Maintenance and upkeep of color sorter

1. Maintenance of color sorter body

1.1 Daily maintenance and upkeep content

1.1.1 Use an air gun to clean the dust inside the chute.

1.1.2 Gently wipe the dust or oil stains on the outer surface of the sorting box glass with a soft cloth.

1.1.3 Check if there are any foreign objects in the vibrator slot. If there are, they can be wiped off with a soft cloth.

1.1.4 Use an air gun to blow away the dust above the nozzle. (Note: Do not direct the air gun towards the nozzle to prevent dust from being blown into the nozzle hole).

1.2 Monthly maintenance and upkeep content

1.2.1 Use an air gun to carefully clean the dust and debris adsorbed on each circuit board to prevent them from becoming damp and moldy, which may cause circuit board faults.

1.2.2 Check the cleaning effect of the brush. If the effect is not good, manually wipe it with a soft cloth.

1.2.3 Wipe the surface of the groove with a soft cloth.

1.2.4 Turn on the power and check the working condition of each injection valve. If there is any leakage or no blowing, open the "Valve Test" interface on the touch screen to test the solenoid valve at that hole position.

1.2.5 In case of special circumstances such as power outage, program failure, etc., the power supply of the color sorter should be immediately cut off, and the machine should be restarted when there is no external impact.

1.2.6 Conduct regular maintenance on the color sorter once a month, including checking if the lamp brightness is normal, if the solenoid valve is working, if the LED flashing frequency of the color sorter is normal during operation, and if the color selection effect is normal.

2. Maintenance and upkeep of air compressors, air storage tanks, and dryers

2.1 The air compressor and air storage tank should be filled with water once a day.

2.3 Check whether the dryer is running well every day, and after running for 30 minutes, check whether the drainage system is normal.

During winter, check daily whether the air filter, oil mist separator, and other places are frozen. If they are frozen, manually drain the water.

2.5 Regularly clean the filter element of the filter every month.

2.6 Remove the automatic drain regularly every month for cleaning.