Provide efficient sorting solutions for various types of grain

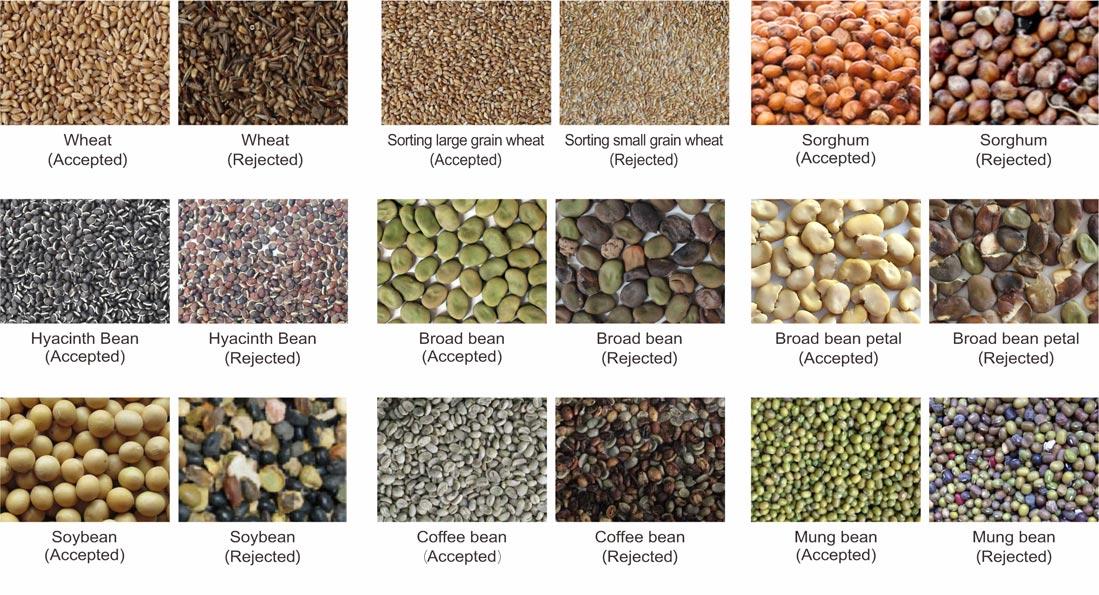

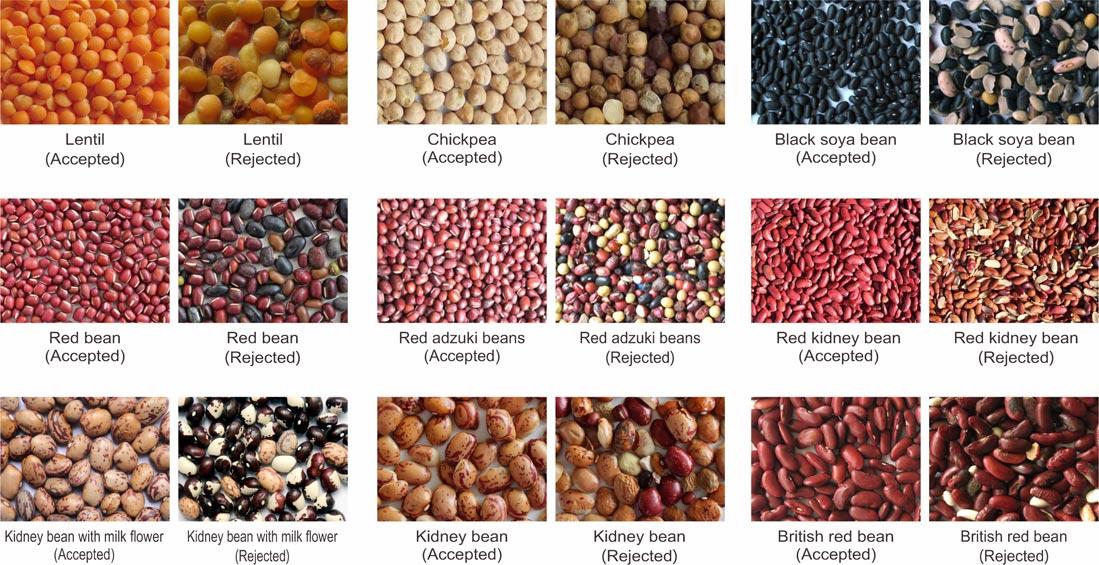

Mihoshi Grain Multi purpose Color Sorter is widely used to meet your different needs. It is suitable for sorting and grading miscellaneous grain materials such as corn, wheat, soybeans, red beans, mung beans, lentils, white kidney beans, milky beans, broad beans, chickpeas, peanuts, quinoa, millet, sesame, oats, barley, barley, sorghum, etc. Efficient removal of impurities such as discolored particles, moldy particles, soil blocks, small stones, glass, desiccants, etc. It has the characteristics of a stable high-precision sorting system, high production, energy saving, simple operation, convenient use, and long service life.

Product Introduction

Suitable for grain sorting and grading, equipped with infrared sorting system sorting machine models, ultraviolet sorting system machine models, and AI deep learning technology sorting models, it can remove impurities such as discoloration, mold, soil blocks, stones, glass, plastics, desiccants, etc.

Adopting a stable high-precision sorting system, the impurity sorting effect is good. Double the production of cutting and mixing. High yield, energy-saving, simple operation, convenient use, and long service life.

Application Field

Applied to the sorting of corn, wheat, soybeans, red beans, mung beans, lentils, white kidney beans, milky beans, broad beans, chickpeas, peanuts, peanuts, quinoa, millet, sesame, oats, barley, highland barley, sorghum and other miscellaneous grain materials.

Product Specificities

Real time monitoring and intelligent management: Our devices are equipped with real-time monitoring systems and intelligent management software, utilizing artificial intelligence technology for data analysis and decision support. This enables operators to monitor equipment status in real-time, analyze production data, and predict and solve potential problems, improving production efficiency and reducing failure rates.

Diversified operation: The intelligent operation interface supports diverse operation methods, such as touch, gesture, voice, remote control, etc., to adapt to different users' usage habits and operation needs.

Customizability: FPGA processors have programmable features and can be flexibly customized and configured according to application requirements. Users can design and adjust logic circuits according to their own needs to achieve specific functionality and performance optimization.

Real time monitoring and feedback: The intelligent remote control system can monitor the status and data of devices or systems in real time, and timely feedback the monitoring results to users, helping them understand the real-time situation and make corresponding decisions and adjustments.

High precision image acquisition: The intelligent visual image acquisition system adopts advanced image acquisition technology and high-resolution sensors, which can obtain image data with high precision, ensuring that the collected images are clear and rich in details.

Efficiency: High quality solenoid valves have low energy consumption and high work efficiency, which can effectively save energy and resources, and improve production efficiency while reducing costs.

Flexibility and adjustability: Balanced feeding systems typically have the function of flexible adjustment, which can be adjusted according to different processes and requirements. The feeding speed, quantity, and frequency can be adjusted as needed to adapt to different production conditions and requirements.

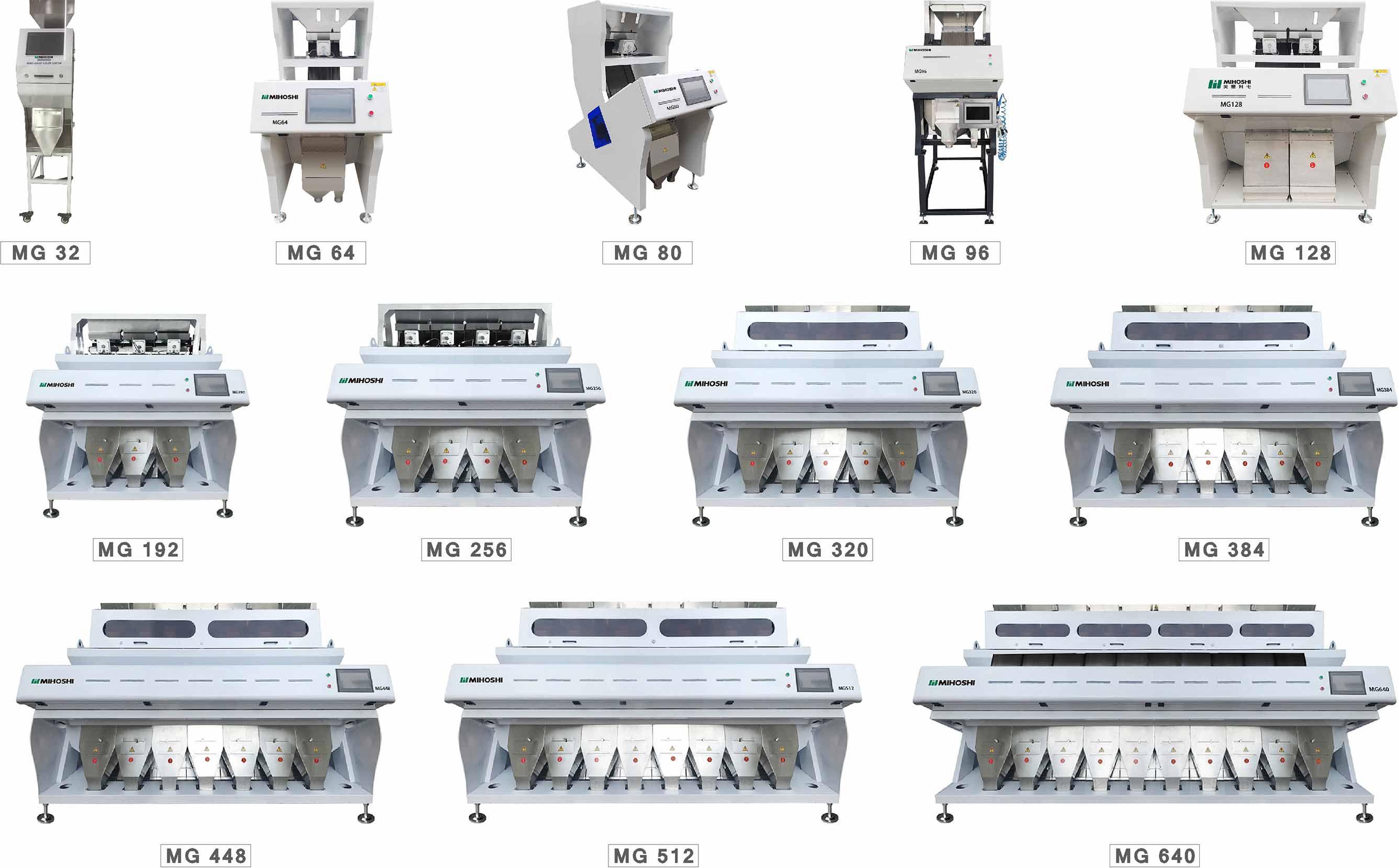

Product models of Chutes color sorter (MG Series)

Sorting Examples

Technicial Specifications

| Product model |

Capacity (T/h) |

Accuracy (%) |

Voltage (V/Hz) |

Power (kW) |

Air pressure (Map) |

Air consumption (L/min) |

Weigh t(Kg) |

Dimension (mm) |

| MG32 | 0.2-0.5 | >99.99% | 220/50 | 0.5-0.8 | 0.6-0.8 | 0.1-0.3 | 120/180 | 590X1504X1760 |

| MG64 | 0.8-1.6 | >99.99% | 220/50 | 0.8-1.5 | 0.6-0.8 | 0.3-0.8 | 300/350 | 880X1504X1760 |

| MG80 | 1-2 | >99.99% | 220/50 | 1-1.8 | 0.6-0.8 | 0.3-0.8 | 350/400 | 900X1504X1760 |

| MG96 | 1-3.5 | >99.99% | 220/50 | 1.2-1.8 | 0.6-0.8 | 0.4-0.9 | 300/400 | 1550X940X1750 |

| MG128 | 2-6 | >99.99% | 220/50 | 1.3-2.2 | 0.6-0.8 | 0.5-1.0 | 700/860 | 1314X1504X1760 |

| MG192 | 3-9 | >99.99% | 220/50 | 1.5-2.5 | 0.6-0.8 | 0.8-1.5 | 950/1000 | 1650x1504X1760 |

| MG256 | 4-12 | >99.99% | 220/50 | 1.8-3 | 0.6-0.8 | 1.0-2.0 | 1100/1200 | 1986X1504X1760 |

| MG320 | 5-15 | >99.99% | 220/50 | 2.2-3.7 | 0.6-0.8 | 1.3-2.1 | 1280/1350 | 2322x1504X1760 |

| MG384 | 6-18 | >99.99% | 220/50 | 3.6-4.5 | 0.6-0.8 | 2.0-3.5 | 1400/1500 | 2658X1504X1760 |

| MG448 | 7-21 | >99.99% | 220/50 | 4.1-5.5 | 0.6-0.8 | 2.5-4.3 | 1500/1600 | 2994x1504X1760 |

| MG512 | 8-24 | >99.99% | 220/50 | 4.7-6 | 0.6-0.8 | 3.0-4.5 | 1700/1800 | 3330X1504X1760 |

| MG640 | 10-30 | >99.99% | 220/50 | 4.5-7.5 | 0.6-0.8 | 5.0-6.5 | 2000/2250 | 3666X1504X1760 |

| MG768 | 12-38 | >99.99% | 220/50 | 5.2-8.8 | 0.6-0.8 | 7.0-8.5 | 2500/2600 | 4200x1504X1760 |

Installations Case

Our strengths